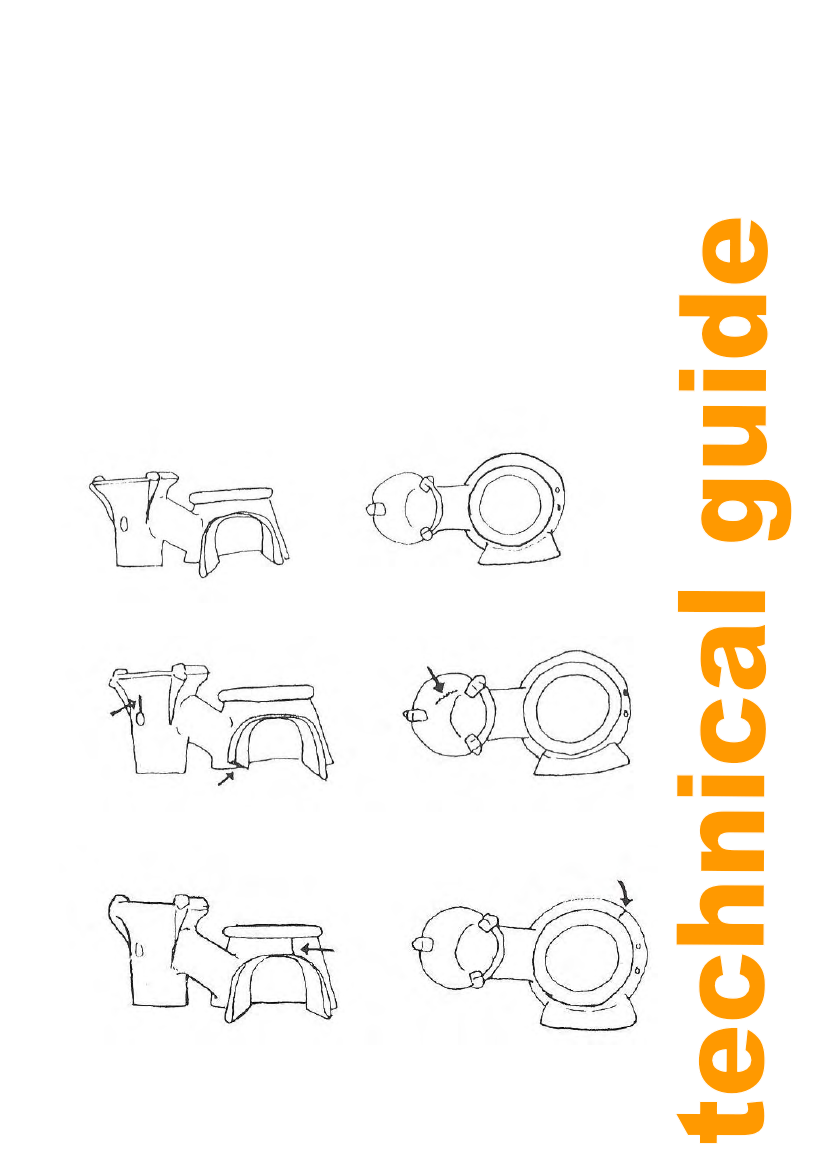

How to make Sri Lanka’s anagi II stove

Practical Action

In traditional Sri Lankan potters kilns, the stoves should be fired for a longer time than is

required for pots. The extra thickness of the stoves requires more time for the heat to

penetrate.

In either kiln, the firing temperature range is 850 - 900°C. Darker-firing clay should be fired

at the lower temperature; lighter-firing clays are better fired at or around 900°C. The top of

the tile factory kilns is fairly hot, and the clay composition must be adjusted to the higher

temperature. It has been found that mixing sand and extra grog into the tile clay has

prevented overfiring problems. The clay mix currently in use is 8 parts tile clay: 1 part sand:

1 part grog (by volume).

Quality Control after Firing

After firing, the stoves must be checked for cracks or unacceptable warping. The thick rims

of the design should prevent warping of the process, keeping them a desirable round circle

rather than an egg-shape.

Stoves are placed in 3 categories: Grade A, which sells for full price; Grade B, which sells for

half price, and Rejects, which are not sold at all.

Grade A: no cracks

Grade B: cracks in the baffle, cracks or chips in the door piece, or a crack anywhere on the

second pothole piece.

Rejects: any crack, no matter how small, in the firebox.

29